Food Processing Sanitation

.

.

.

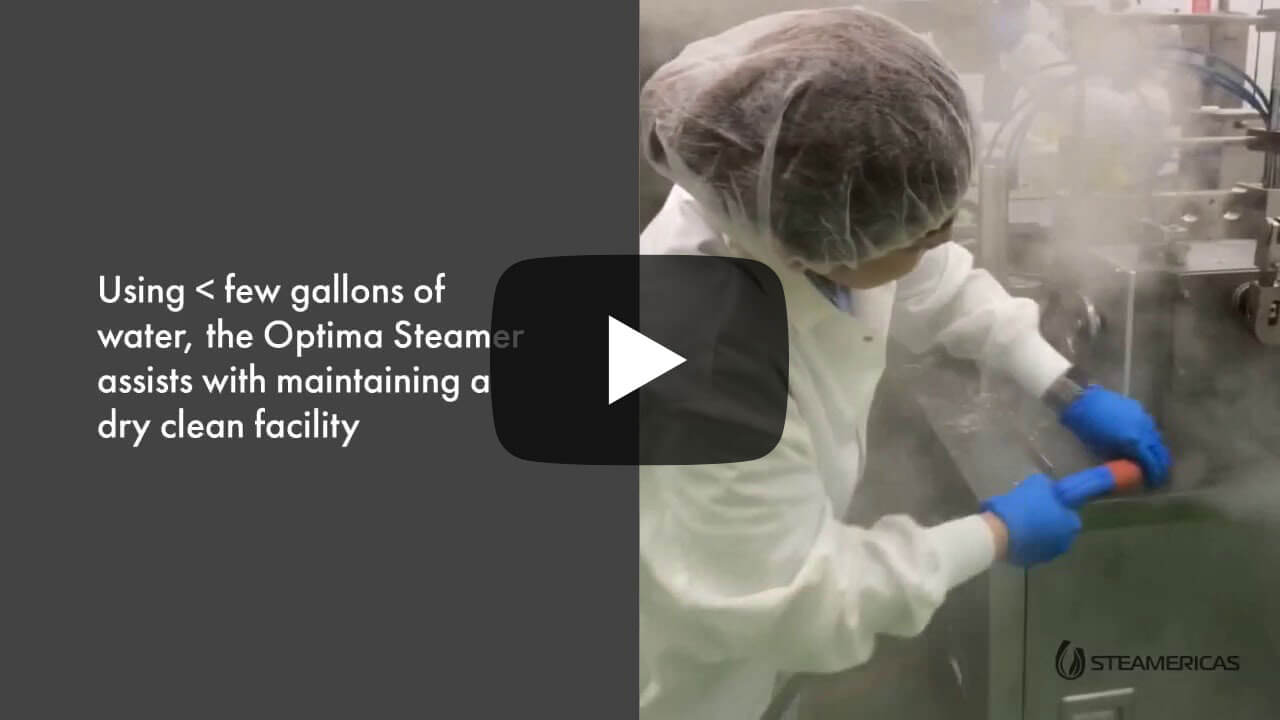

The Optima Steamer™ for Food Processing Sanitation & Cleaning

Our powerful, user-friendly line of industrial dry-vapor steam machines will help you easily comply with regulatory codes and laws—such as FSMA (Food Safety Modernization Act), all while saving time, saving resources and saving money. Whatever your food processing sanitation needs are: spot cleaning, CIP/COP/SIP/SOP, or even specifically conveyor belt cleaning and sanitation, the Optima Steamer™ is the right choice. View our validated log reduction tests on common pathogens here.

Straight to the Point: The Optima’s Features and How Dry Steam is a GAME CHANGER for Food Processing Sanitation

The OPTIMA STEAMER™ -vs- Hot Water/Wet Steam

Temperature

DRY STEAM reaches temperatures well above 212°F, water’s boiling point and what makes it a gas.

Hot water and/or wet steam (delivered by hot water pressure washers without a true boiler) only create diffused water particles or mist, and the output is below 212°F.

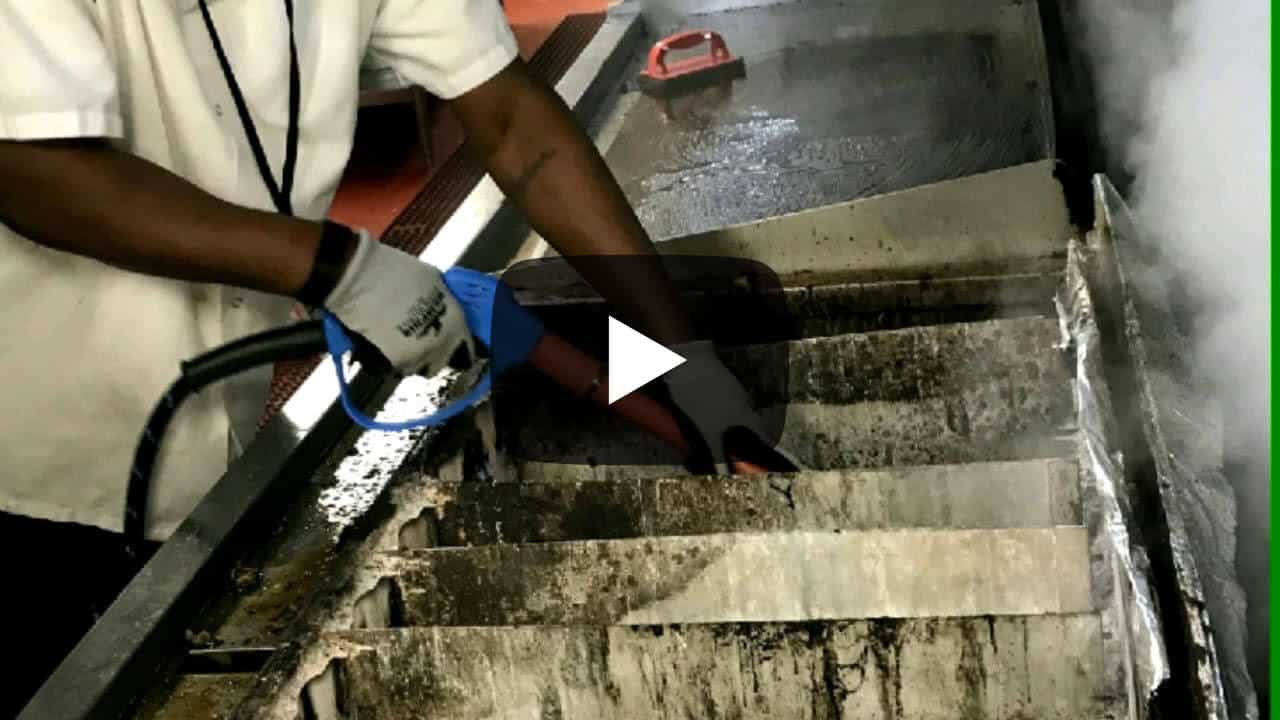

Surface Penetration

DRY STEAM, being gas, can penetrate surfaces quicker and further—delivering sanitizing temperatures deeper, faster.

Hot water and/or wet steam takes time penetrate into surfaces and the lower temperatures aren’t as effectively transferred.

Waste Water

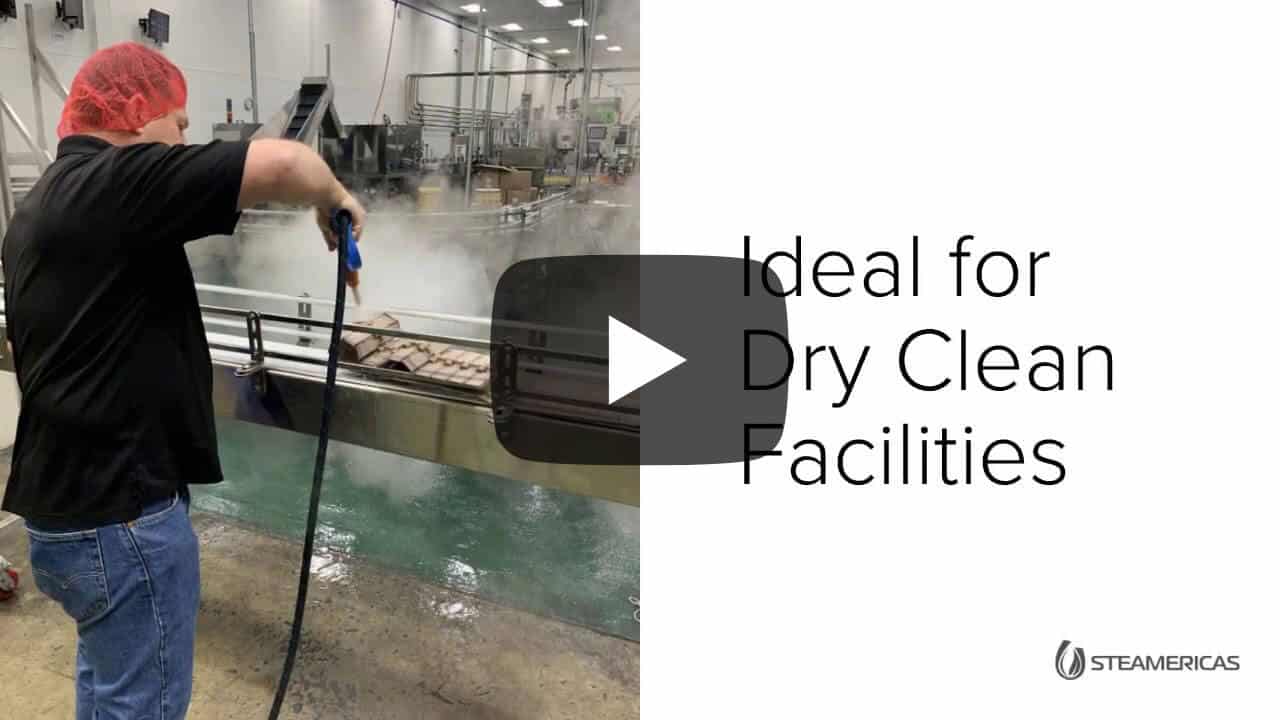

DRY STEAM is a gas and has far fewer water molecules, producing little to NO waste water—perfect for dry clean facilities.

Hot water and/or wet steam leads to runoff and requires drainage—bad for cleaning and sanitation.

The Optima Pneumatic Conveyor Belt Cleaning Tool

Eliminate the hassles and manpower of disassembling, moving, washing, drying and reassembling conveyor structures out of place. Save money by reducing water consumption and the use of chemicals. The Optima Conveyor Belt Cleaning Tool uses a pneumatic-driven system to carefully and precisely deliver the Optima’s powerful, sanitizing steam jet to every inch of belts up to 60 inches wide as they run, eliminating the need for stopping production.

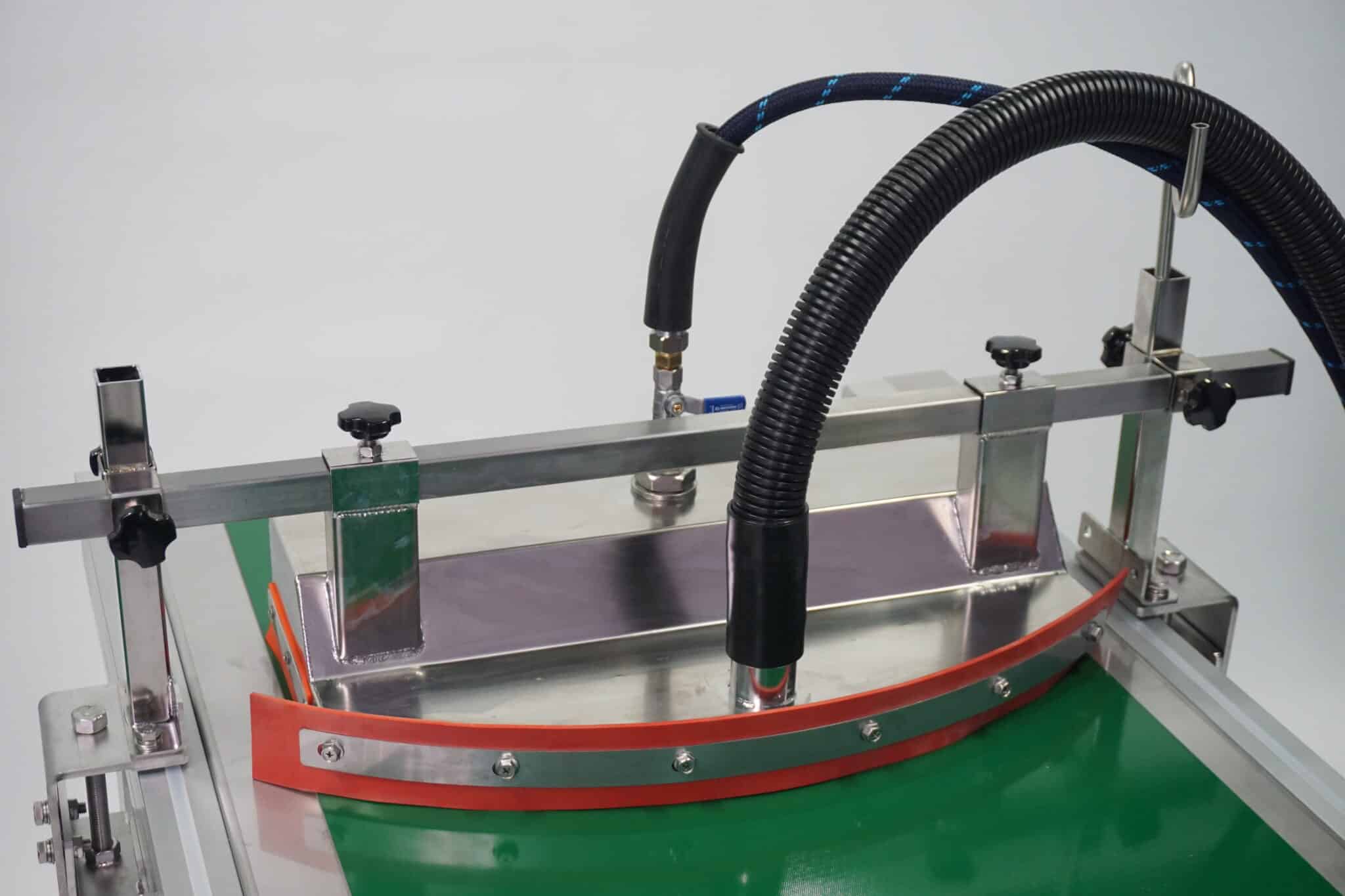

The Optima Vacuum-Ready Conveyor Belt Cleaning Tool

Powerfully clean and sanitize flat belts up to 20 inches wide while leaving behind a virtually dry surface. Tackles chocolate, sugar residues, fats and sticky substances with no waste water, no overspray, no harsh chemicals, and no downtime! The position can be adjusted for larger belts, allowing for complete cleaning in multiple passes.