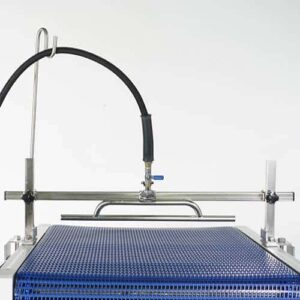

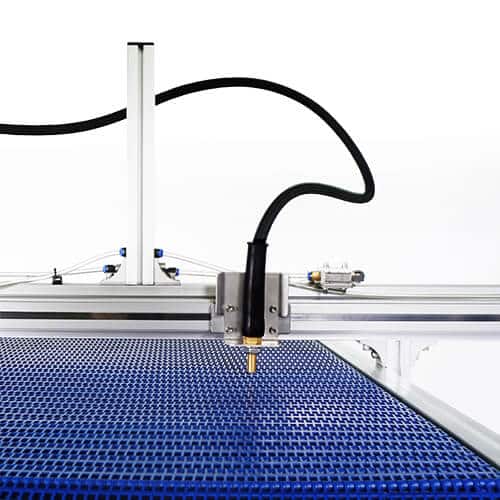

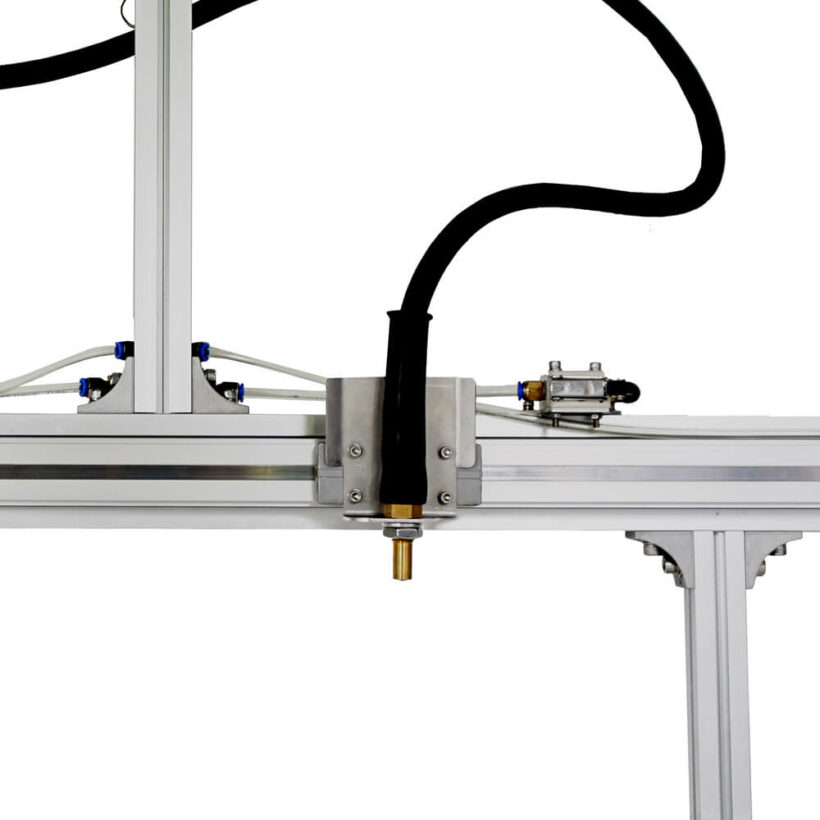

Pneumatic Conveyor Belt Cleaning Tool for 48-inch Belts

$6,825.00

Pneumatically driven by an air compressor*, this oscillating conveyor belt cleaning tool mounts on the belt to clean and sanitize in place. The moving steam head is fully adjustable to deliver the full power of the the steam jet to entire surface of the belt, maximizing the cleaning and sanitizing power for belts up to 1.5 meters (60in) wide.

In stock

| Weight | 53 lbs |

|---|---|

| Dimensions | 56 × 33 × 11 in |

| Country of Origin | Republic of Korea (South Korea) |

| Dimensions (as shipped) | 81 x 34 x 12 in, 66 lbs |