Incorporating Dry Vapor Steam Into Disinfection Processes Against COVID-19

Introduction to Dry Vapor Steam

A dry vapor steam cleaner or generator is designed to produce saturated and superheated steam typically with pressures ranging between 60-145 psi and temperatures in the range of 307-363°F. Dry vapor steam refers to water in its purely gaseous state, being completely heated above and beyond the 212°F/ 100°C boiling point. It has relatively low pressure but high temperature ratings.

Dry vapor steam is widely used in food, beverage and other manufacturing industries for its natural (thermal) sanitizing effects and gaining popularity among mobile washers thanks to its (water) runoff-free cleaning process.

While high temperature accompanied by dry vapor steam can remove or inactivate most known microorganisms–including viruses–there are certain limitations to its applications stemming from unique characteristics of dry vapor steam.

Understanding the novel coronavirus (SARS-CoV-2)

Viruses are protein cells that can only grow inside a host such as humans. They are not truly “alive” on their own and cannot be “killed.” However, a virus can be inactivated or its infecticity can be affected by chemicals and other disinfectants, as well as environmental factors such as temperature and humidity. Viruses can survive on surfaces from a few hours to a few days depending on the type of surface and environment. Virus pathogens can travel in droplets of saliva from human to human and recent studies suggest it can also become airborne.† Based on its structure, SARS-Cov-2 is believed to be highly sensitive to heat and moisture, but highly contagious. SARS-Cov-2’s viral envelopes are of lipid layers. Enveloped viruses like SARS-CoV-2—which rely on a protective lipid coating—are the easiest type to deactivate. In contrast with many gastrointestinal viruses like norovirus which have a tough protein shell called a capsid, viruses with this fatty wrapping are relatively vulnerable.††

† New coronavirus may spread as an airborne aerosol, like SARS from Live Science

†† “How we know disinfectants should kill the COVID-19 coronavirus” from Chemical & Engineering News, “Viral Envelope” from Wikipedia)

Thermal removal or inactivation of pathogens

Using temperatures of 80°C (176°F) or higher on contact surfaces is known to remove most bacteria and inactivate most viruses. With extended exposure time from a few seconds to 30 minutes (depending on the pathogen)—even at 60°C (140°F)—temperature is able to remove or inactivate pathogens. WHO recognizes viral inactivation by heat and recommends boiling drinking water in the regions where communicative diseases are common.†

Steamericas’ validation reports show that dry vapor steam generated by the Optima Steamer was able to remove listeria, e-coli, salmonella, and staphylococcus among other common pathogens.† A major cleaning equipment manufacturer claims that even a household-sized steam cleaner has efficacy against enveloped viruses such as influenza and other viruses in the coronavirus family when used properly based on their study.†††

† WHO Technical Brief: Boil Water

†† Lebrun Labs Efficacy Studies on the Optima Steamer

††† Steam Cleaners Against the Coronavirus by Kärcher Group

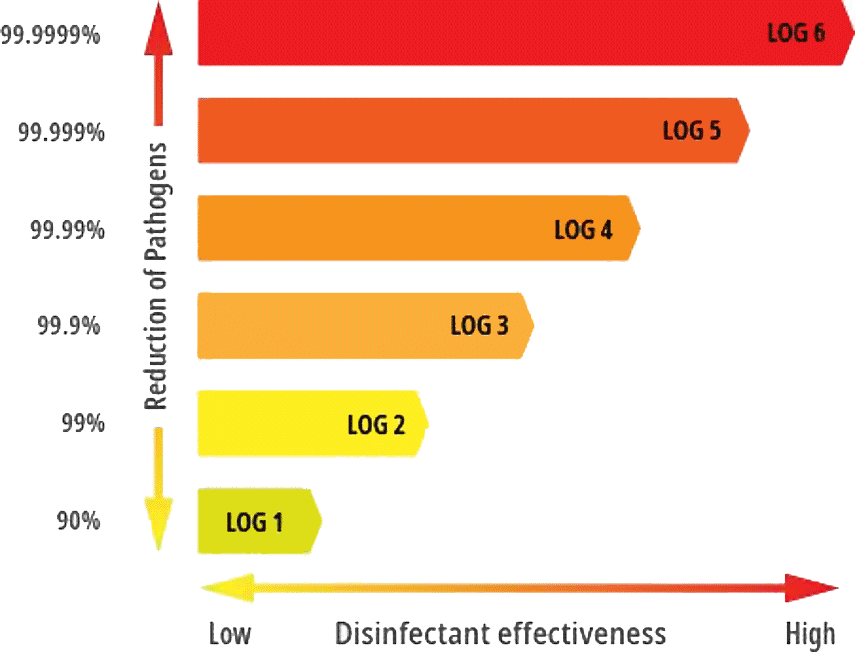

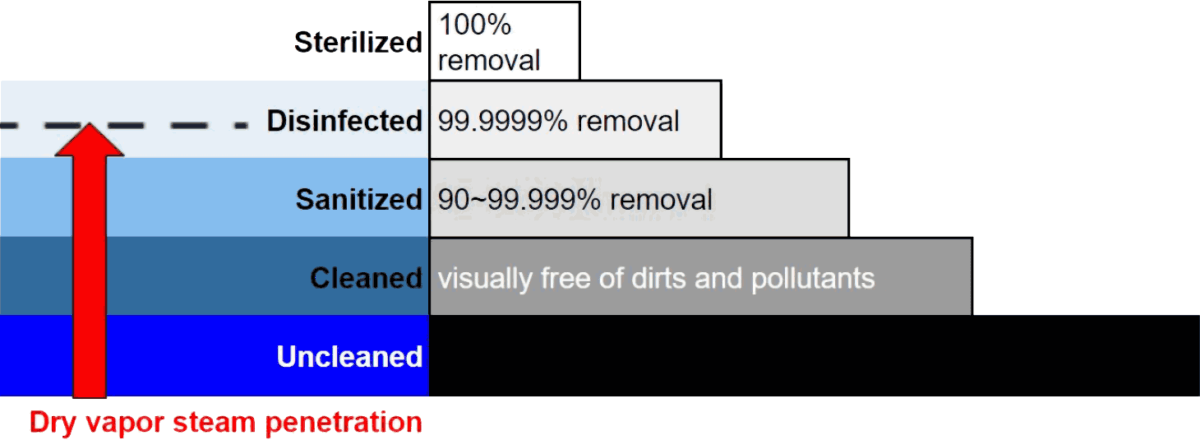

Understanding differences among Cleaning, Sanitizing, Disinfecting and Sterilizing

There is often a confusion among these terms, particularly between sanitizing and disinfecting. It is paramount for a sanitation professional to understand the differences and what a particular sanitation protocol is expected or intended to achieve. The COVID-19 pandemic is caused by a virus and “disinfection” is the main goal.

These are simple definitions of each process:

- Cleaning: removing visual particles from surfaces

- Sanitizing: removing or deactivating pathogen quantities down to an “acceptable” level, often by a 1 to 5 log reduction (90-99.999%).

- Disinfecting: removing or deactivating unwanted microorganism quantities down to 6 log reduction (90-99.999%).

- Sterilizing: 100% removal or inactivation of microorganisms

Dry vapor steam is proven to both clean and sanitize. Dry vapor steam is capable of disinfecting in controlled environments where lethal temperatures can be guaranteed.

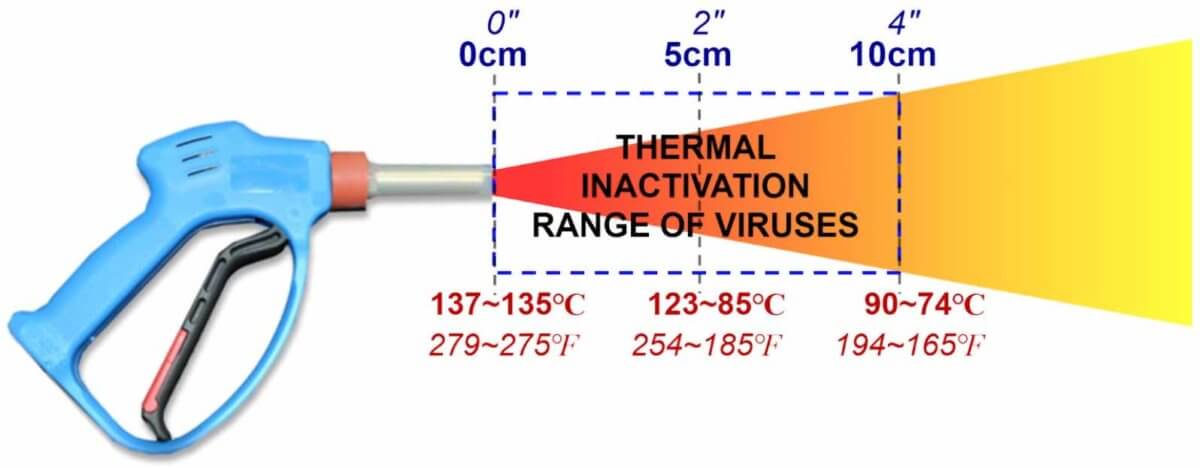

Dry vapor steam temperature

To achieve temperatures above saturation (212°F/ 100°C), steam must be pressurized or contained. Again, dry vapor steam is water purely in the state of gas, therefore it acts like air. Steam’s temperature and pressure cannot travel as far as a hot water jet, for example. Its temperature and pressure drop exponentially once it exits from a pressurized vessel. In reality, unless steam is being fed into a contained space or used in controlled environments, it is very difficult to predict the temperature on the contact surface. The graphic below illustrates how steam’s temperature decreases based on the distance between the steam gun nozzle and the contact surface. These temperatures were measured using the Optima Steamer XD commercial steamer, which rates the boiler’s operating temperature at 350°F/178°C when operated in an ambient temperatures of 65°F/18°C.† The consistency of the steam jet’s volume and temperature affect the residual heat capacity as well. When comparing two steamers with identical steam temperature ratings, a steamer that produces a higher volume of steam will transfer higher temperatures to contact surfaces due to its higher residual heat capacity.

Sanivap–a European dry vapor steamer manufacturer that focuses on disinfecting application markets–published dry vapor steam’s validation reports against viruses, including a strain of virus in the coronavirus family in 2015.†† In this study, a mop attachment was used to contain the steam, increasing the residual heat capacity as much as possible.

The distance to contact surface, ambient temperature, and the residual heat capacity of steamer equipment must be considered accordingly to achieve successful thermal disinfection.

† Optima Steamer Steamer Temperature from Gun Nozzle by SJE Corporation

†† Efficacy on Viruses on Multi-resistant Microorganisms by SaniVap

Cases for and against dry vapor steam in disinfecting efforts

Concerns surrounding using dry vapor steam for disinfecting purposes can be summarized as following:

- Ensuring contact surface temperature (keeping very close distance, which makes for a longer process)

- Ensuring contact surface time, which could take anywhere from <1 second to >30 minutes of exposure time depending on the pathogen and temperature being used

- There is no documented 6 log reduction data on viruses in the coronavirus family currently.

On the other hand, dry vapor steam has many practical benefits.

- Flexible usage / no waste-water runoff (i.e. deployment during business hours)

- No residual chemical cost, just soft water which is much more economical and accessible.

- Better penetration on porous surfaces

- Appropriate for chemical-sensitive environments

- Safe for human inhalation

- No hazmat storage or training required

Examples

As practical examples, South Korea has been using dry vapor steam in conjunction with sodium hypochlorite based chemical treatments in disinfecting “phone booth-style” COVID-19 testing stations inside hospitals.† Seoul Metro has been disinfecting subway trains with hydrogen peroxide based electrostatic misting systems and dry vapor steam for upholstery and human contact surfaces.††

† South Korea’s Phone Booth Coronavirus Testing Stations disinfected with dry vapor steam Steamericas Youtube channel

†† Seoul Subway Trains Receive Deep Clean As South Korea Reports A Jump In COVID-19 Cases by NBC News

Recommended steps

As demonstrated above, dry vapor steam has benefits and shortcomings regarding deployment. Due to environmental constraints in deployment of dry vapor steam and incomplete knowledge of the new virus, it is advised that dry vapor steam is used in conjunction with EPA approved disinfectants† for combating COVID-19 at this present time. However, it should be noted that disinfectants should never be added directly to steamer’s water tank or boiler as doing so will not only damage the equipment and is harmful and unsafe to the user, but also may compromise the chemical bond and integrity of the disinfectant’s active ingredient from being exposed to high temperature above its boiling point.

The following steps are recommended.†

- Wear proper personal protective equipment (PPE): N95 or better mask, goggles, gloves and a full suit are recommended to protect sanitation professionals against inhaling chemicals and exposure to the virus.

- Clean first: Remove visible particles first before disinfecting (Steam can be used for cleaning in certain cases)

- Use proven disinfectant chemical recommended by respective government†

- Use steam to remove chemical residue and/or to utilize heat to inactivate remaining viruses

-Keep distance of 4” or less between nozzle and surface.

-For upholstery, use steam on contact for better heat transfer.

† The Optima Steamer and COVID-19 Steamericas Youtube channel

†† List N:Disinfectants for Use Against SARS-CoV-2 by EPA

Conclusion and Disclaimer

The COVID-19 causing virus known as the novel coronavirus is so new that at this present time, there is no validation available for steam specifically for SARS-CoV-2. The above information and recommendations are based on existing scientific data regarding known pathogens and viruses in general. Currently, using dry vapor steam is recommended as an additional tool to enhance sanitation, not as a sole “disinfectant” to combat COVID-19.