Craft Breweries

Sanitize and Restore the Foeders in Your Craft Brewery

Using steam is the perfect way to sanitize in your craft brewery. Foeders have similar cleaning challenges as barrels being wood. In addition, they are very large. Steam can restore and fill in the gaps between foedor staves and sanitize effectively and relatively quickly. The fastest and most eco-friendly way to sanitize every nook of the surface is using wet heat, a.k.a. saturated steam. Unlike hot water or wet steam (water vapor), saturated steam (a.k.a. dry steam), which is the gaseous form of water that carries heat, can travel far and around obstacles and reach areas that hot water in liquid form cannot. The Optima Steamer has a flow rate of 0.08 gallon per minute (per regular sized steam hose). It takes about 5 gallons of water to sanitize and swell a 3500~4500 gallon foedor. Energy spent to boil only 5 gallons of water versus the alternative (thousand gallons of water) equates to big savings on your power bill. Using less water and energy is not only friendly to your wallet but also to the environment.

Steam is the Superior Method of Barrel Sanitizing. Period.

The Optima Steamer generates steam temperatures around 350°F and is capable of delivering temperature of 212~240°F at the nozzle tip in ambient temperature and pressure. When steam is fed to a barrel or tank and lightly pressurized, it can reach much higher temperature in a relatively short time.

You can use the Optima as a stand alone cleaning station to sanitize 2 barrels simultaneously. For larger facilities, the Optima can be paired with an automatic barrel washer line and loading system, cleaning 4 barrels at a time.

Paired with our barrel tool, dry steam penetrates wood’s surface and pores. Because of its gaseous properties, steam can reach ¼~½” into wood where brettanomyces lives, using moisture and temperature to kill hidden bacteria naturally. Steam’s saturated vapor is able to penetrate better than heat alone, making it ideal for reaching difficult areas that are often impossible to reach using boiling water or chemicals like ozone. Amongst competitors, the Optima Steamer delivers steam at a higher, more consistent pressure more quickly, which equates to higher temperatures and saving time.

The Optima Steamer…

KILLS MOLD, BACTERIA and YEAST

Steam is proven to effectively and rapidly inactivate most microorganisms. At a temperature of over 212°F (100°C) for 5-10 min, steam will destroy all active bacteria, yeast, and fungi. While some yeast strains are known to be resistant to low pH, high alcohol and/or SO2, dry steam will combat these microbes known to cause spoilage.

EXCEEDS SAFETY STANDARDS

The Optima SE-II is designed to the highest international standards, including OSHA-approved (bearing ASME and NB stamps) and CSA-certified (Canadian-compliance) models, all with a sleek, self-contained design so that you can be rest assured your business and staff are safe operating an Optima Steamer.

SANITIZES SUSTAINABLY

The Optima Steamer uses a fraction of water during wine barrel sanitation, creating high temperature steam to kill microbes. The lack of wastewater and the eliminated need for chemicals is eco-friendly and allows wineries to operate in compliance with the Clean Water Act.

Watch the Optima Steamer Swell a Barrel

in Minutes, Not Hours

Dry steam rehydrates barrels while sanitizing them, and it can accomplish this in a matter of just a few minutes and with only about half of a gallon of water per barrel. Pressurized steam quickly penetrates wood’s surface and pores, killing microbes deep in the wood while delivering moisture that fills the gaps between staves.

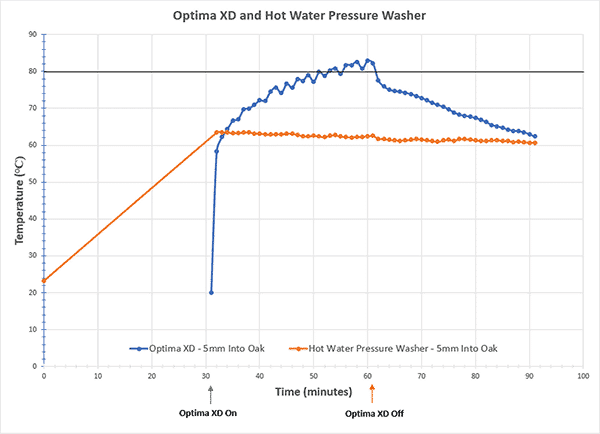

Reach 200°F+ Inside Tanks in Record Time

While the use of water and chemicals fed through a pressure washer with rotating nozzles may suffice cleaning requirements, sanitizing internal surface of tanks (stainless steel, concrete and HDPE plastic) requires more science. Most microorganisms are eliminated when exposed to a certain temperature for a certain period of time. The fastest and most eco-friendly way to sanitize every nook of the surface is using wet heat, a.k.a. saturated steam. Unlike hot water or wet steam, saturated steam (a.k.a. dry steam), which is the gaseous form of water that carries heat, can travel around obstacles and reach areas that hot water in liquid form cannot. In a case study, the Optima Steamer SE 42kW was able to deliver 200°F temperature throughout a 6,000 gallon stainless steel tank within 40 minutes.* This is done chemical-free and uses only a few gallons of water.

*The time will obviously vary depending on the ambient temperature, tank material/thickness and steam hose size.

High Temperature Bottling Line Sanitation

Wine Barrel Steam Tool

Mounted on the barrel, this tool securely and safely pressurizes barrels with a vented silicone bung. Includes an industrial grade thermometer for accurate temperature readings.